The Making of The Rovers

Then

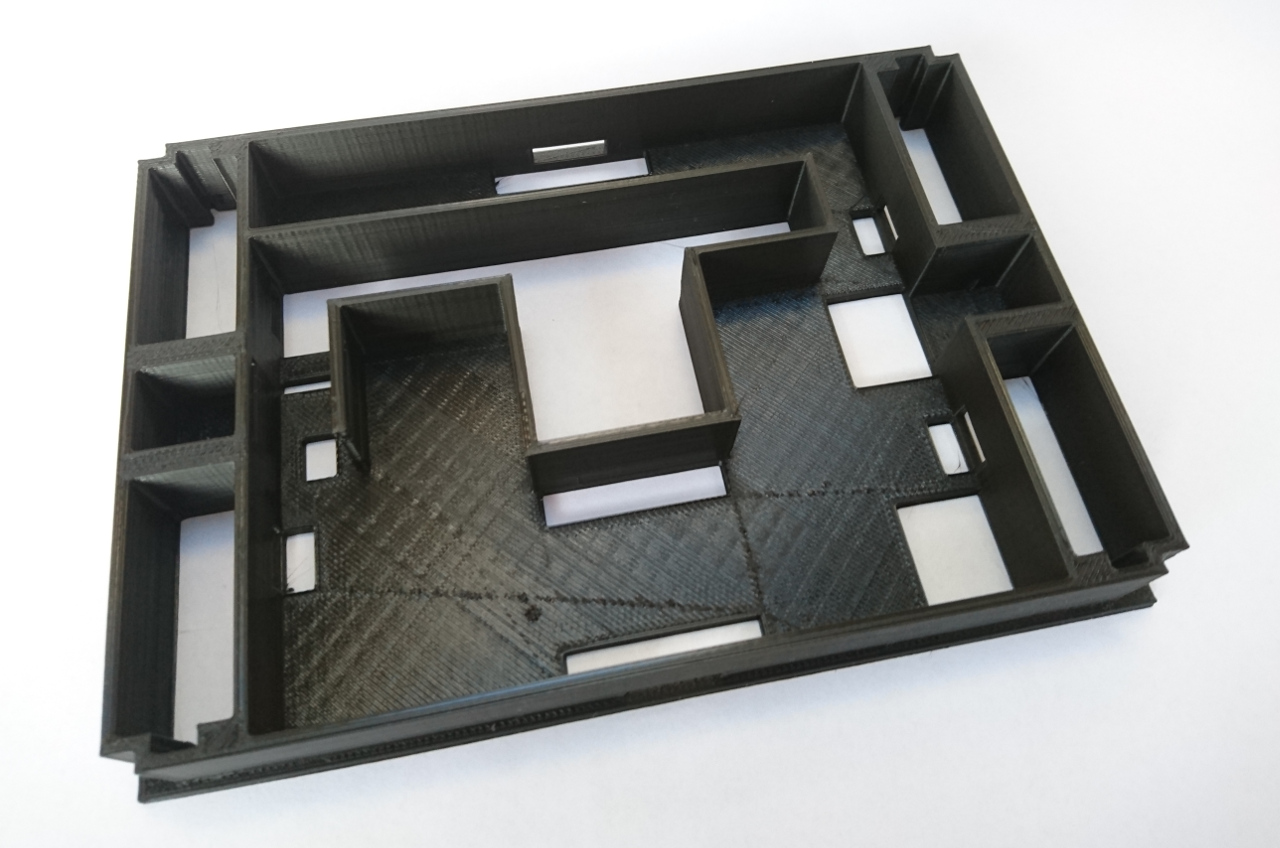

The cardboard prototype was perfect for getting the approximate size of the chassis and position of the steering servos but not good for rigidness.Original idea was for steering servos to be placed along length of the rover for making it even more rigid. Unfortunately it wasn't the best idea as amount of space on the 'first floor' of the rover wouldn't be used in the most optimal way. Type (and size of the battery) dictated that long and narrow space was needed and servos on the side would have used it all. On the other hand, placing the servos perpendicular left enough space for battery to be placed on its side, on the side of the rover next to the hole for the camera. Length of the battery and size of the servos defined our rover's footprint: 160mm x 110mm. A few prints of the main chassis and we've settled down to exact measures, the position of the Raspberry Pi on the top of it and gap needed for camera to operate under the rover and over.

A few prints of the main chassis and we've settled down to exact measures, the position of the Raspberry Pi on the top of it and gap needed for camera to operate under the rover and over.

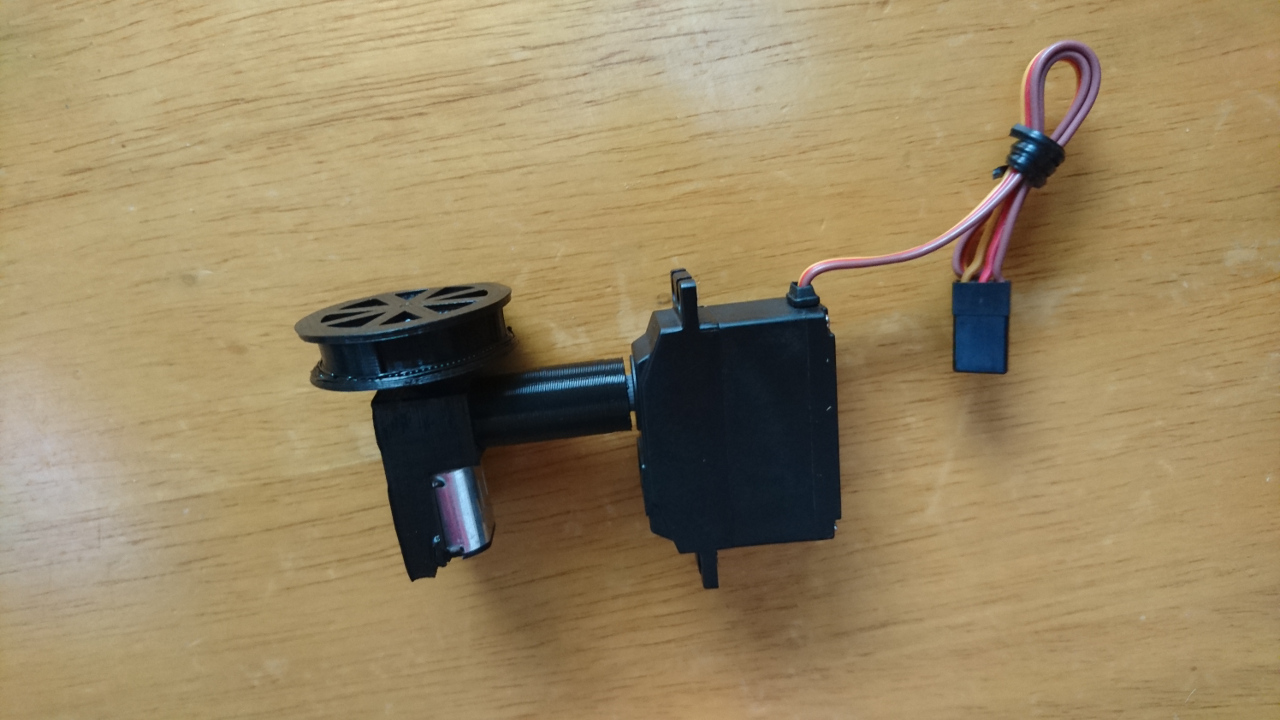

Also, wheels need tyres:

Also, wheels need tyres: