Prototyping

It is time for prototyping again! For our first PiWars we adopted iterative approach: design, mock, test, improve and repeat. That lead to lots of iterations and lots of discarded parts.

But was that necessarily a bad thing? So far it seems that at least half of the 'previous versions' have found a kind of home - for people who wanted to try putting together a rover of ours and are not worried having the latest, the most refined version of it. Also, it helped us to find out what the 'dead ends' and the 'wrong decisions' were like and we learned from them. Beside that, it made our club members not be scared of trying out stuff even if it originally seems not to be the best idea that we can come up with at that moment.

Now we are at quite a few new designs. One of the first we did was PiNoon capture nut (ahm, electric connector) and with distance sensor (VL53L0X). One of the previous blogs was about capturing stuff in 3D printer objects.

Guess what we will be doing on our next club meeting on Wednesday! :)

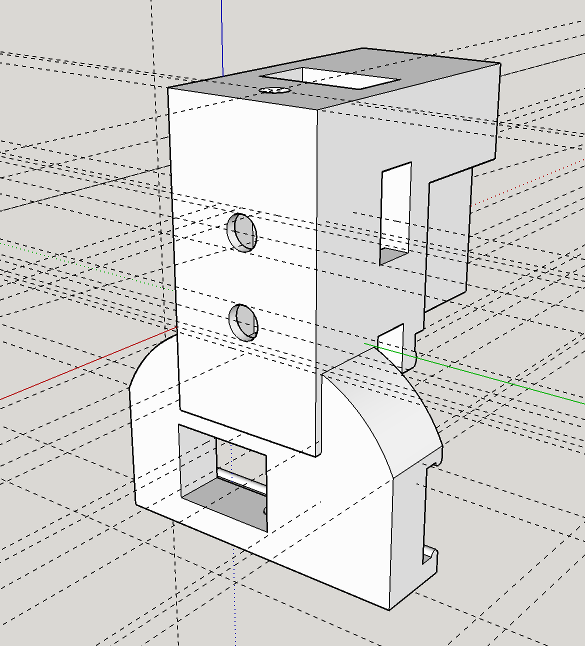

Guess what we will be doing on our next club meeting on Wednesday! :) One of such a design decision was the way camera arm is attached to the servos. Idea was that if appropriate retched hole is made, servo shaft would fit and hold. It did to the extend but whole connection was a bit flimsy and would easily slip. Calibrating camera servos and then having the arm slip on the servo shaft would cause even more damage (or add to slipping, rounding the hole even more). The solution for this is to incorporate the original servo arms to the 3D printer parts. The result is here:

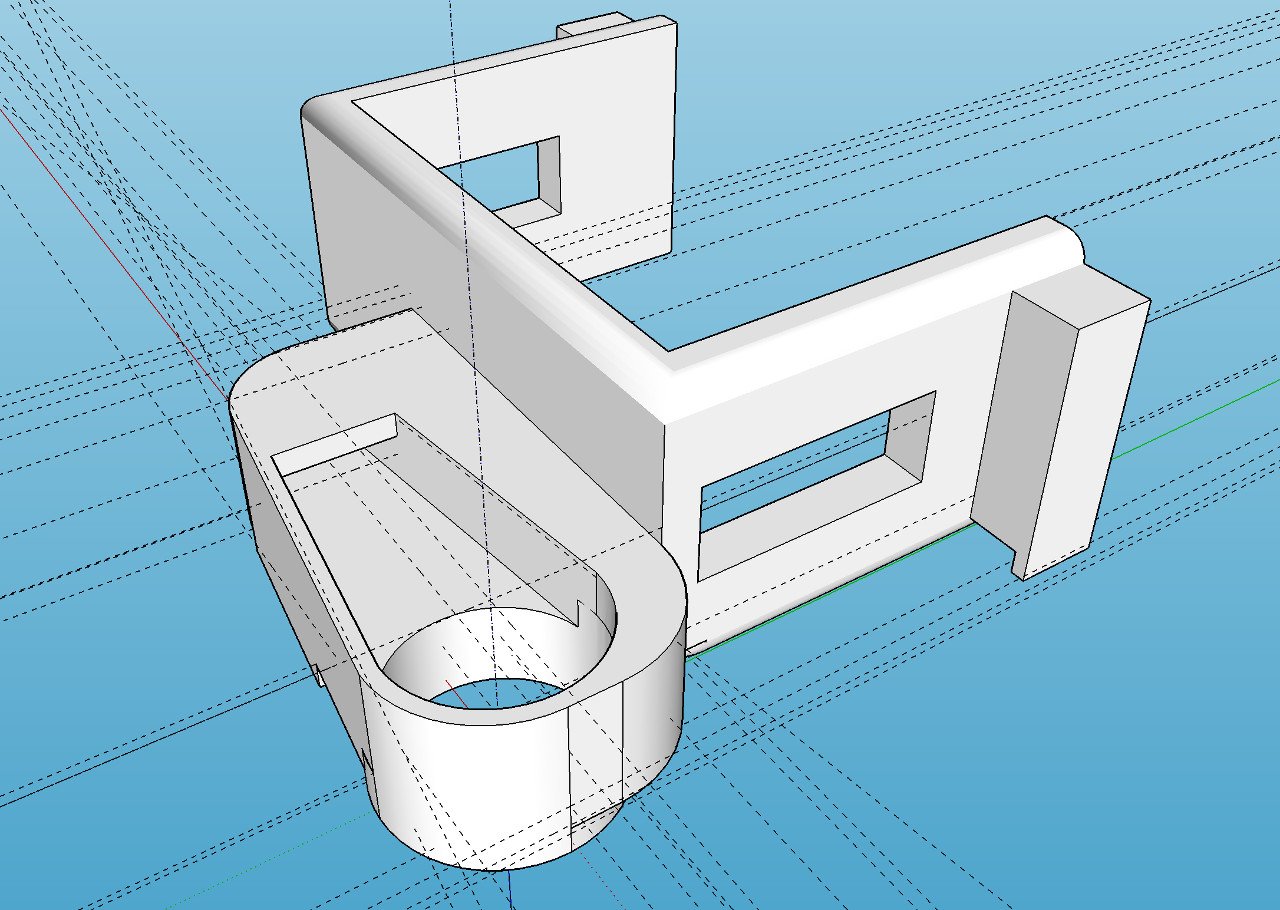

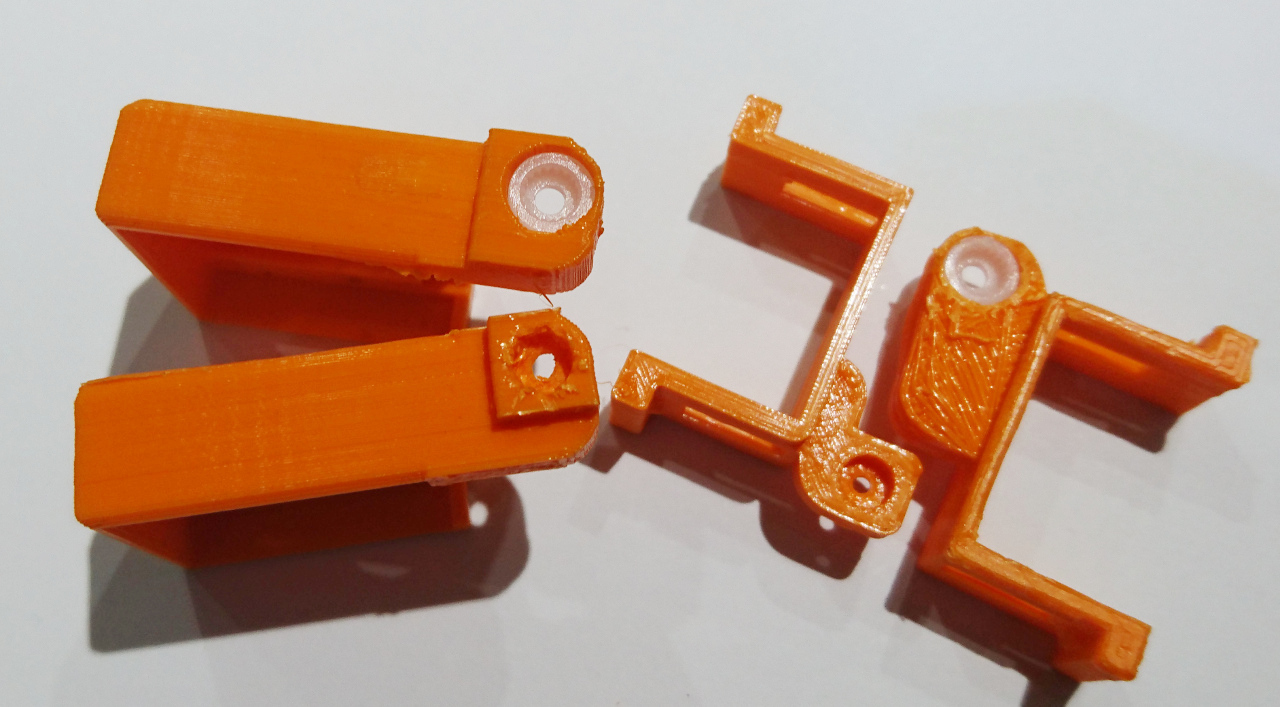

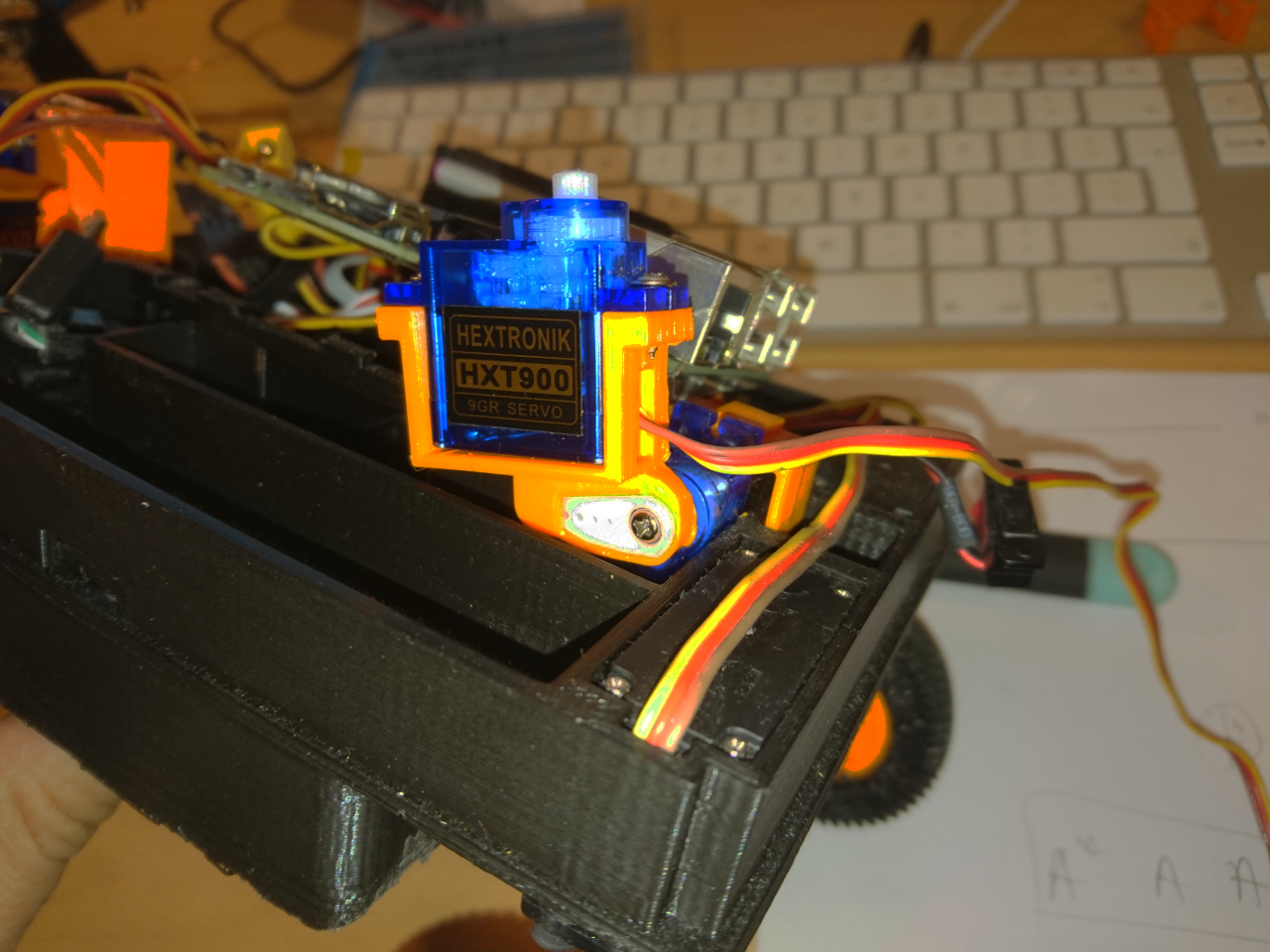

One of such a design decision was the way camera arm is attached to the servos. Idea was that if appropriate retched hole is made, servo shaft would fit and hold. It did to the extend but whole connection was a bit flimsy and would easily slip. Calibrating camera servos and then having the arm slip on the servo shaft would cause even more damage (or add to slipping, rounding the hole even more). The solution for this is to incorporate the original servo arms to the 3D printer parts. The result is here:

Getting ready for the challenges

Getting ready for the challenges